Adding value through sustainability, product safety, quality, and continuity

In today’s heparin market it is not enough to just meet high standard specifications, it requires expertise to add such value through sustainability, product safety, quality, and continuity. It’s why we deploy our expertise to ensure maximum control of the supply chain and production process

- high-quality crude heparin, fit for all conventional processes towards heparin API

- thorough control over our complete supply chain

- guaranteed full traceability of all our crude heparin made from the intestinal mucosa

- carefully controlled sourcing of our porcine mucosa on contracted locations

Expertise

With many years of experience and expertise in the animal by-products industry, we know what is needed to work in full compliance with strict safety and quality procedures.

We source our porcine intestinal mucosa from selected slaughterhouses, that fully meet the quality standards for the sourcing of animal co-products for manufacturing APIs.

Leading pharmaceutical companies all over the world use our crude heparin to manufacture both unfractionated heparin (UFH), as well as low-molecular-weight heparin (LMWH).

To avoid degradation or decay, the intestinal mucosa is directly stabilized and stored in dedicated tanks. The mucosa is subsequently transported – under the supervision of Hepac – to our processing facility using dedicated tank trailers.

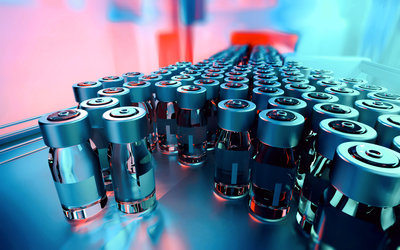

The manufacturing process of our crude heparin is divided into two stages, carried out in our facilities in Burgum and in Loenen in the Netherlands:

- In Burgum, the first stage in the production of crude heparin, heparin is released from the mucosa using enzymatic hydrolyses. The heparin is subsequently bonded to resin.

- In our facility in Loenen, the heparin is desorbed from the resin, precipitated, and dried.

Traceable

We want you to know what you’re getting. Working closely with our sister company CTH – as well as certified and EU-approved slaughterhouses – our supply chain is fully transparent: from farm to pharma.

All our porcine intestinal mucosa is fully traceable in both directions of the supply chain. Such transparency ensures you can count on crude heparin that meets even the highest quality and safety standards.

Quality and compliance

Quality is key. For the manufacture of heparin API formulations, pharmacopeias make it mandatory to use raw materials from pigs ante and post-mortem approved for human consumption by the veterinarian authorities. Because we source in countries with a strong adherence to regulations only, we can guarantee that the porcine intestinal mucosa applied fully meet all such legal requirements.

The same stringent transparency and quality levels are applied to all other materials used in the heparin manufacturing process, such as resin, enzyme, and more. And you can rest assured in the knowledge that all our daily operations comply with industry guidelines, a fully integrate quality management system, supplier qualification program, change control, deviation control, and validation are in everything we do.

We work in full compliance with ICH-Q7 Good Manufacturing Guidance for Active Pharmaceutical Ingredients and the EU Guidelines for Good Manufacturing Practice Part 2, applicable for the stage of the supply chain. We are GMP-certified by the Dutch Government and certified by the Dutch Food Authority (NVWA). Hepac facilities are registered and approved by the Dutch Health Authorities (IGJ), European Medicines Agency (EMA) and the US Food and Drug Administration (US-FDA). Hepac cooperates fully with customer audits.

Product Safety

Hepac guarantees a product that is free of any foreign contamination. This is achieved by applying the highest-level hygiene protocols at the slaughterhouses and the Hepac plants, and full quality control throughout the supply chain.

Continuity

We source our porcine mucosa from certified slaughterhouses across Europe. The geographical spread in suppliers means we can guarantee supply continuity.

This steady flow of raw material – in combination with robust processes and state-of-the-art process equipment – ensures you can count on the highest delivery reliability.

Sustainable

We care for the environment and the earth’s natural resources. A comforting thought, when you use Hepac crude heparin. Animal co-products are inherent to the production of meat. Re-purposing animal co-products from meat production is a sustainable activity by nature. Nevertheless, we set ourselves even higher goals when it comes to sustainability.

For instance, our sister company Sonac processes protein that is a by-product from our crude heparin manufacturing process, that would otherwise go to waste. Using a patented process, Sonac turns protein hydrolysate into a value-adding ingredient for animal feed.